Old quarries in Giovello.

Old quarries in Giovello.

The layers of schist stretched down towards the River Mallero and across the downwards slopes, alternating with amorphous rock and separated by faults known as “molade”.

The good layers were a few metres thick and the “giovelli”, that is to say the quarries, were given appropriate local names.

The quarrymen, known as “giovellai”, from the place of the sites that were gradually built crosswise along the layers of rock, initially found it easy to extract the stone because it had been well worn by periods of ice and thaw.

Dividing it into sheets created no great problems.

As they proceeded to excavate the rock towards the inside, they had to use fire as they had done previously in the old iron mines.

Fire was essential.

However, even though they used suitable dry wood, it filled the environment with smoke, which irritated their eyes, left a black deposit and took a long time to disperse.

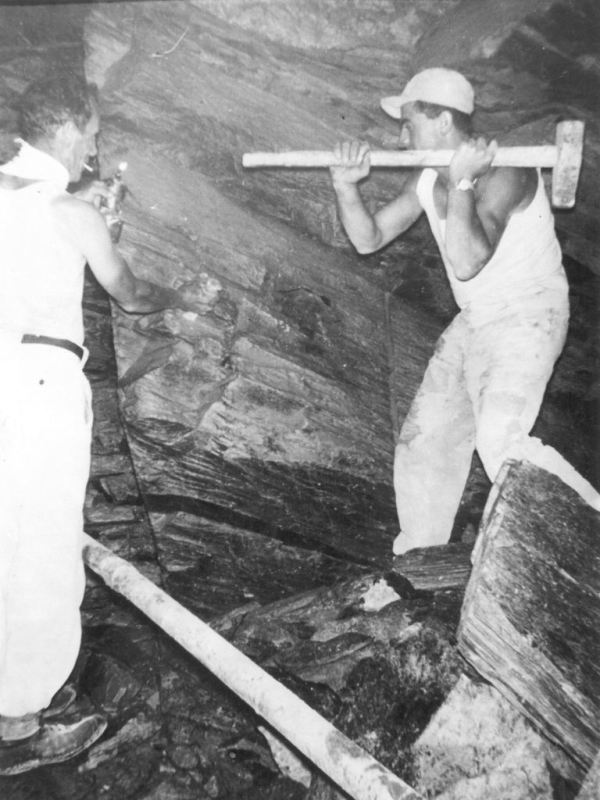

Extraction of the material to create the tiles.

Extraction of the material to create the tiles.

The quarry extended from one main cutting to another, beginning from the right and following the layers for their full thickness downwards.

For safety reasons, once they had entered a short distance inside, they needed to build a wall to the top of the quarry at approximately one metre from the face.

Behind this wall, which became deeper as the work progressed, they stored the waste material produced.

The blocks were extracted by hitting with hammers and wedges.

They were often of a considerable size and were then reduced to “lot” (lots), so they could be carried outside on a man's back or dragged along the steep, impractical outlet.

Naturally, it was dark inside the quarry and in order to be able to work there, it had to be lit.

Lighting came from the fire obtained by resinous wood chips which "maintained the flame" and which they could move.

They also used these chips to light up the outlet, sometimes as deep as 250 – 300 m.

As you can imagine, the work to remove the large stones was very dangerous, as was the transport to the outside along the outlet.