by Ermanno Sagliani

The calchèra was a type of kiln, made of local stone, commonly found in the Alpine area until the beginning of the last century.

Built against the slope partly underground, these small kilns had a circular base of two or three metres in diameter.

They stood three or four metres high, built with imposing, slightly truncated conical-shaped boulders which were narrower at the top.

Used to produce lime for the construction industry, these kilns were built as a result of the good quality limestone available nearby.

In the past, the white limestone boulders,

i sass gianch, were collected in the area and transported to the kilns with the aid of pack mules and shoulder baskets.

Then, they were heated gradually and kept hot for several days.

Wood was passed through a small door at the bottom of the kiln to fuel the fire.

They laid the blocks of lime on the fire and fired them until they obtained quicklime, used to disinfect rooms or, with the addition of sand and water, as a binder in the building trade.

Until the first half of the twentieth century, it was customary to sell the quicklime to the kiln in Tornadri which, in turn, would put it on the local market of the Valtellina.

Otherwise it was used locally.

The calchère were archaic, pre-industrial structures, conditioned by the availability of the raw material and by the restricted requirements of the local construction industry of the time.

The kilns required experience to set up and run, as special attention had to be paid to the temperature, ventilation and fuelling of the fire.

The specialised craftsmen in this trade were called

calcheròtt.

These stone kilns were often used not only to fire the lime, but also to produce charcoal, a natural process during the combustion of wood in the presence of very little oxygen.

The phases of carbonisation were very similar in method and time to those for producing lime.

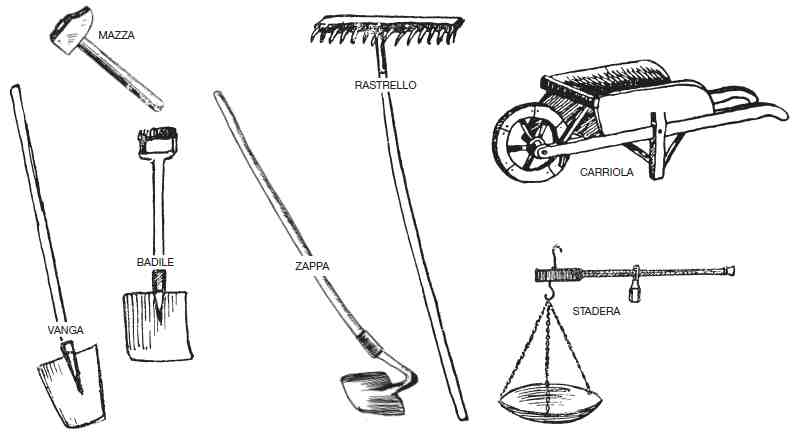

The tools

Some of the tools used to work in the calchère.

Some of the tools used to work in the calchère.

Work tools were few and simple.

Forks and rakes to extract the red-hot lumps of quicklime, spades and hoes to load the kiln and mallets to break the stones.

Women with baskets, men with barrows or packmules would carry the quicklime to be put into sacks and weighed on the weighbeam, after which they were ready for sale.